In a November 5, 2015 posting on the OnTheDash vintage Heuer discussion forum, one of the members of our community (Gianluca) provided a beautifully illustrated, step-by-step description showing the disassembly of a Caliber 15 chronograph movement (known as the “Chronomatic” movement). The Chronomatic was the first automatic chronograph movement, and this family of movements was used by Heuer, Breitling, Hamilton and several other brands from 1969 into the 1980s.

While few of us collectors would even consider undertaking such a project, all of us can learn some important lessons from this posting. Learning about the parts and construction of the Chronomatic movement will help us understand how these machines work, and will also facilitate communications with our watchmakers and other collectors.

For those wondering about Gianluca, he is in his 40s, lives in Italy, works as an electronics engineer for Ferrari GES. That’s right, Ferrari GES (GEstione Sportiva), the Formula One racing department. Gianluca works in research and development, for the electronics of the power train, and also with dyno benches. Of course, his hobby is collecting vintage chronographs, mainly the Heuers.

Creating this sort of posting requires an incredible amount of time and patience, and we thanks Gianluca for this amazing contribution to our community. We know that many enthusiasts will benefit from his efforts.

Jeff Stein

November 12, 2015

++++++++++++++++++++++++++++++++++++++++

Hi all,

Some time ago I started to service some of my watches (the cheapest one, like this Monza, surely not the Monacos 😉 ) and I documented, for myself, all the procedure to disassemble the movement. Until now, I don’t think a similar description has ever been posted, so I hope to please you all showing how an Heuer Caliber 15 (but is the same for a Cal 11 or Cal 12, chronograph module apart) is made, part after part.

I only recommend, if you want to service one, to do it at your own risk. It is easier to damage it, rather than make a good job if you don’t have a bit of experience and don’t know some tricks (I started with a movement bought on Ebay and had the help of an exceptional person..thanks again mate). But neither is it so impossible.

Please note that this posting covers the disassembly of the “watch side” of the Chronomatic movement, but does not show disassembly of the chronograph module. One of the advantages of the modular construction of the Chronomatic movement is that you do not need to disassemble the chronograph module in order to clean it. The complete chronograph module is immersed in the ultrasonic cleaner, with no disassembly required.

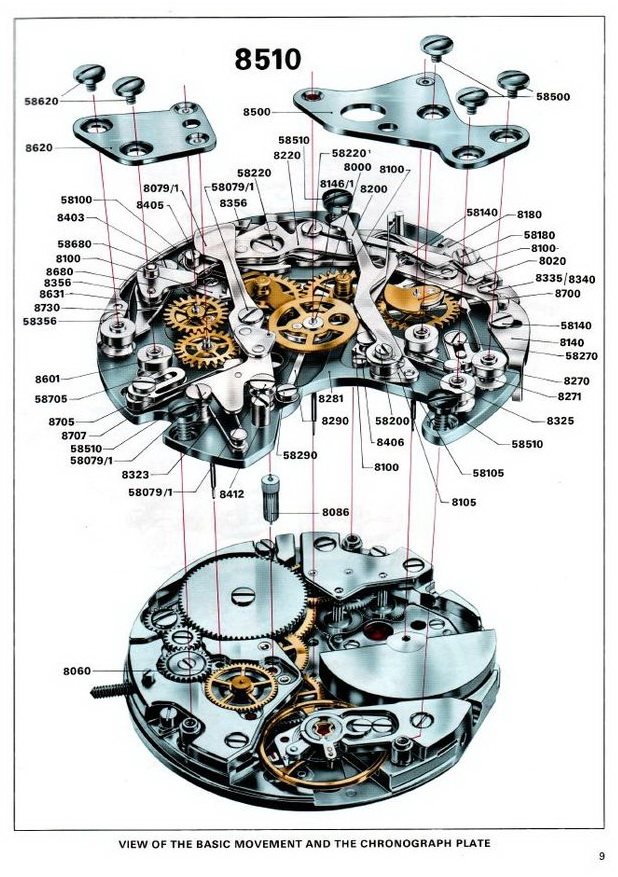

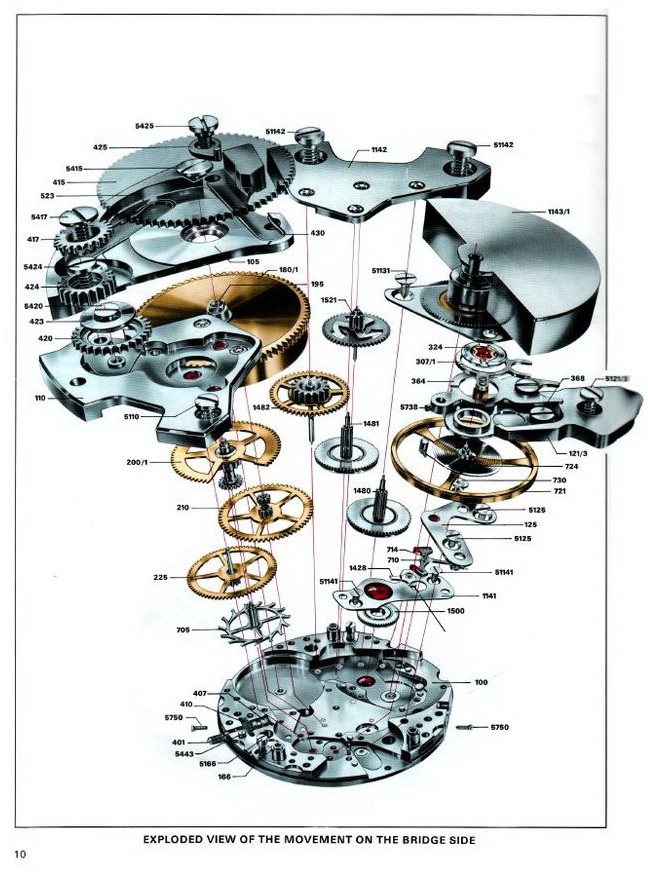

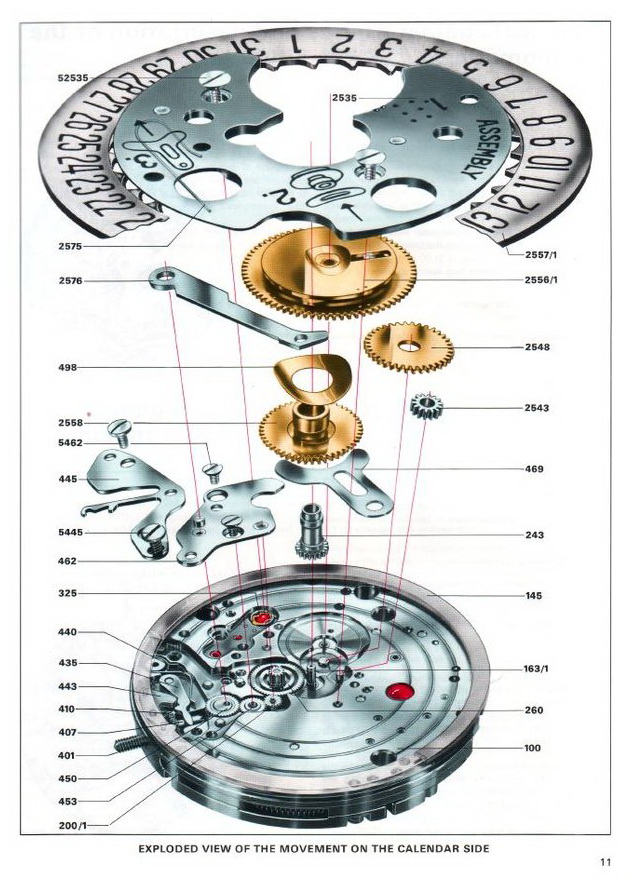

These images are taken from the service manual and contain an exploded of the main parts (the chrono module and the basic movement):

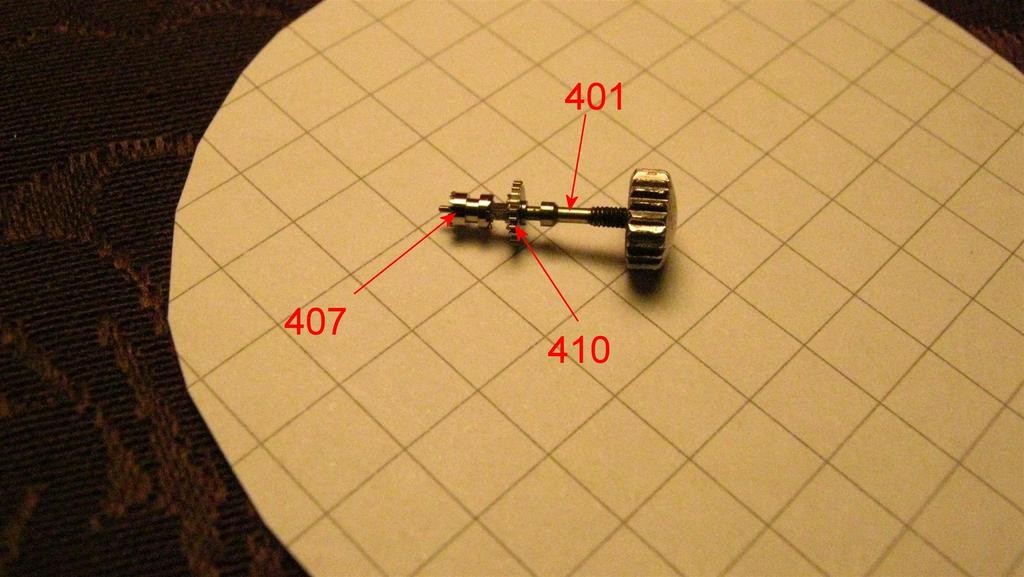

First of all you have to uncase the movement from the case. Assuming you have already opened the case-back start unscrewing the 5443 (sorry the image is wrong, is not 5446) setting lever screw (1.5 turns, not more !!) and pull outward the stem 401, with the crown. Then unscrew the two 5166 casing clamp screws and remove (or simply push inward) the two 166 casing clamps:

Then take the watchmaker’s cushion and put it on the movement, with the movement upside down. Turn the watch together with the cushion and the movement should remain on the cushion while you lift the case.

Next step is removing the hands. You need specific tools to do it and can risk bending or damaging them. I always have a bit of fear every time I have to do it. Anyway, it is a mandatory step and not the argument of this post. To do this, unscrew the two 5750 dial screws (located on the movement side, at 1.30 and 8.30):

Then take apart the 498 washer (very thin; be careful) and the 145 dial rest:

Now put the movement on the clamp and remove the chrono module, unscrewing the three blue 58510 screws (the following image is of a Cal12 movement, not 15, but screws are located in the same place):

Take care because the 8086 oscillating pinion will probably remain attached to the chrono module, so remove it gently (avoid damaging its small teeth, with the pliers):

Take apart and store the chrono module, as isn’t necessary to dismount it; simply wash it with the ultrasonic bath; just some parts like the chrono bridges will be removed after washing for oiling some parts.

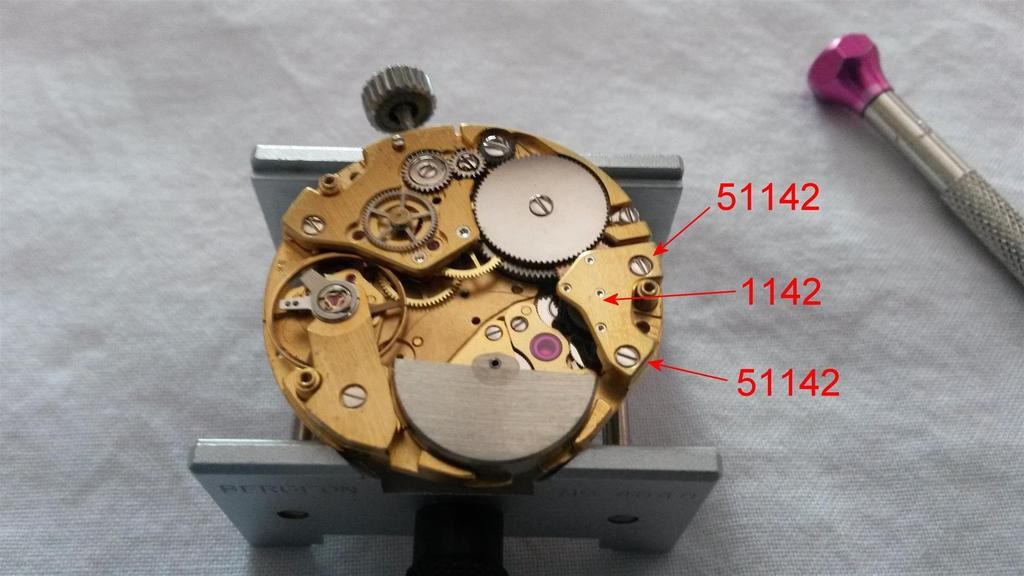

Now let’s start to dismount the main module: remove the 1142 upper bridge for automatic device unscrewing the 51142 screws:

Then remove the 1143/1 oscillating weight (the famous “microrotor”), unscrewing its two 51131 screws (the second one is under the rotor):

The microrotor with its bridge 1131 will appear like this (under the golden bridge there is the gear that allows the recharge):

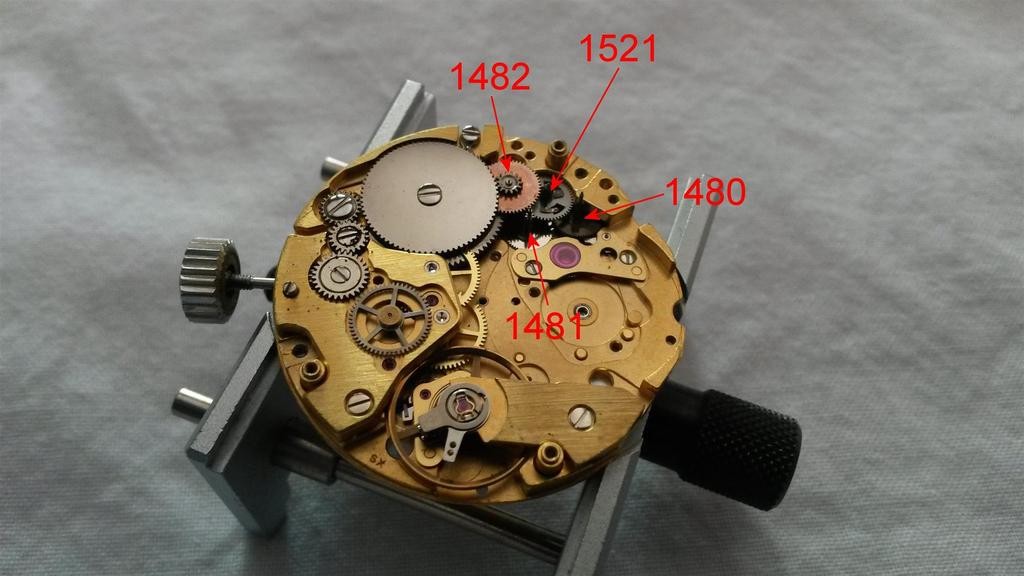

Now remove the four wheels starting from the 1521 coupling wheel, then the 1482 driving gear for ratchet wheel, then the 1480 winding up wheel and 1481 reduction gear (the last two are identical, no problem to store them together):

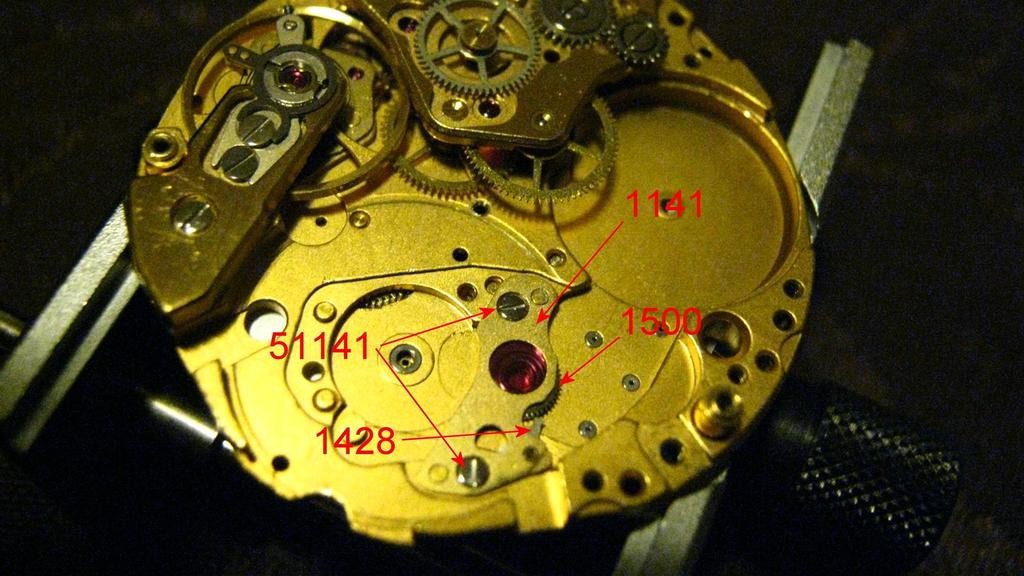

Now it’s the time for removing the 1141 lower bridge for automatic device, the 1500 wig-wag pinion and the delicate 1428 stop click (the one which ensures that the mainspring doesn’t unwind when recharged by the microrotor), obviously unscrewing the 51141 screws:

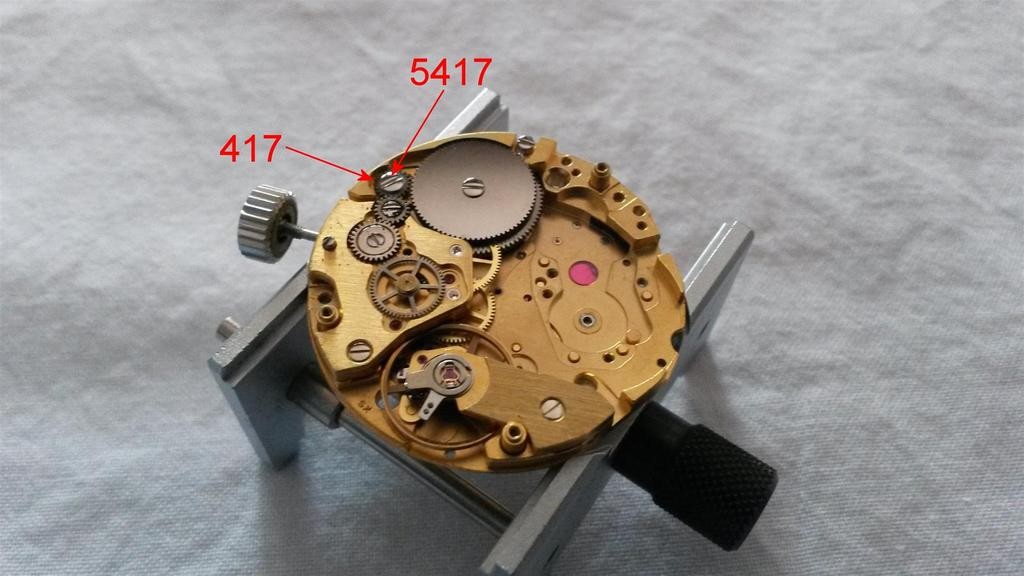

Then remove the 417 intermediate ratchet wheel and its screw 5417:

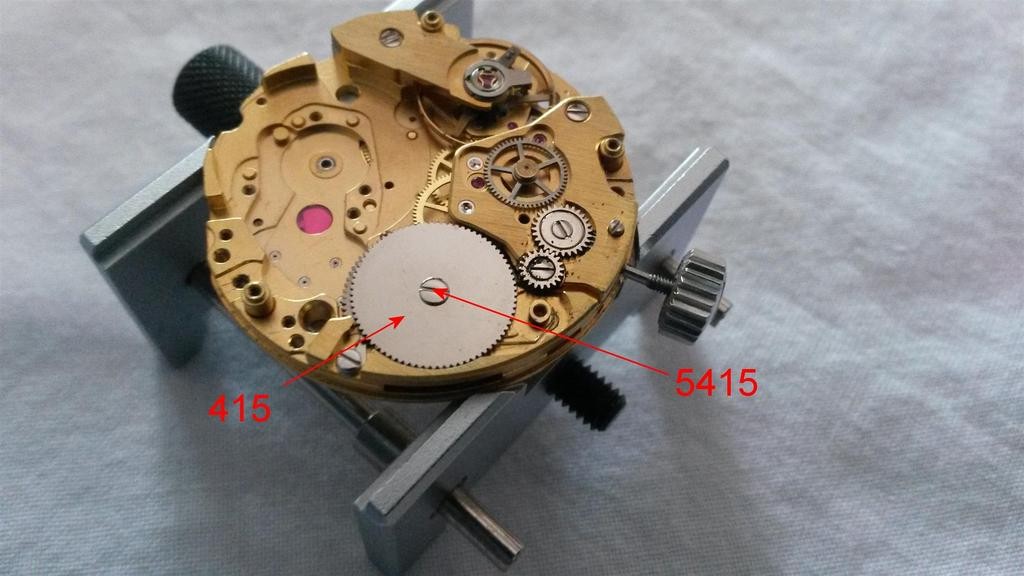

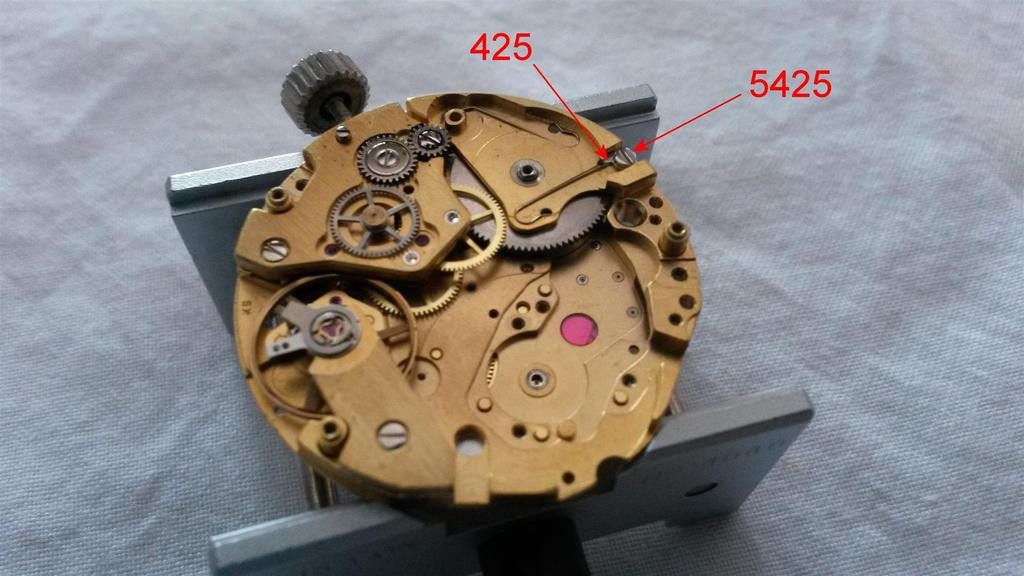

Now remove the 415 ratchet wheel (after unwinding the mainspring, opening gently the 425 click) and its screw 5415:

Now remove the 425 click and its screw 5425:

Remove the 105 barrel bridge BUT leave in place the two springs 430 (click spring) and 523 (setting wheel spring), otherwise they will squeeze into the hyperspace (and you will have a serious problem 🙂 ):

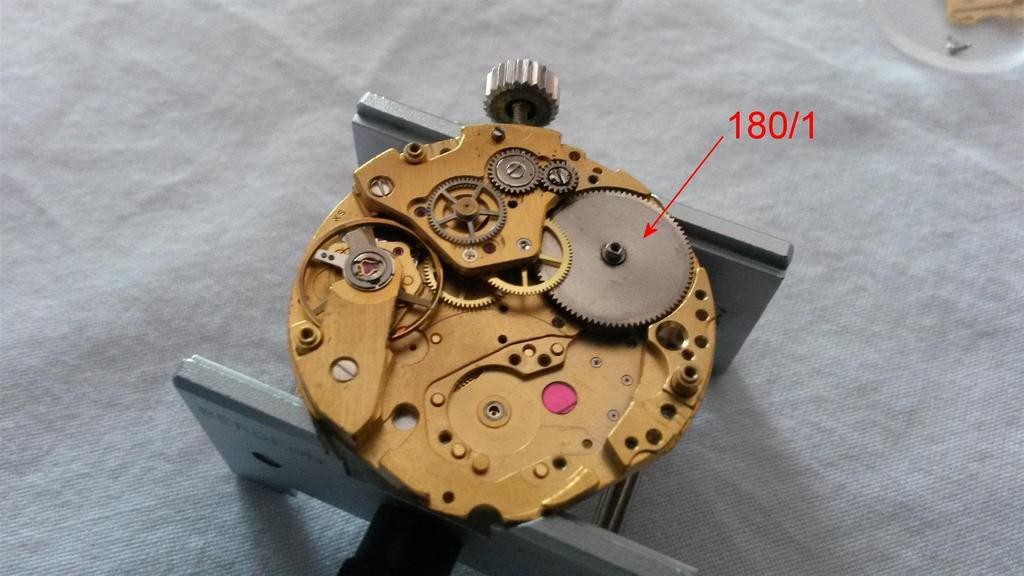

Remove the 180/1 mainspring’s barrel, pulling it up at the opposite side from the 200/1 large driving wheel:

Remove the 424 intermediate crown wheel and its screw 5424, then the 420 (core) + 423 (wheel), taking care that its 5420 screw is a LEFT-HANDED screw (you must “normally screw” to unscrew it):

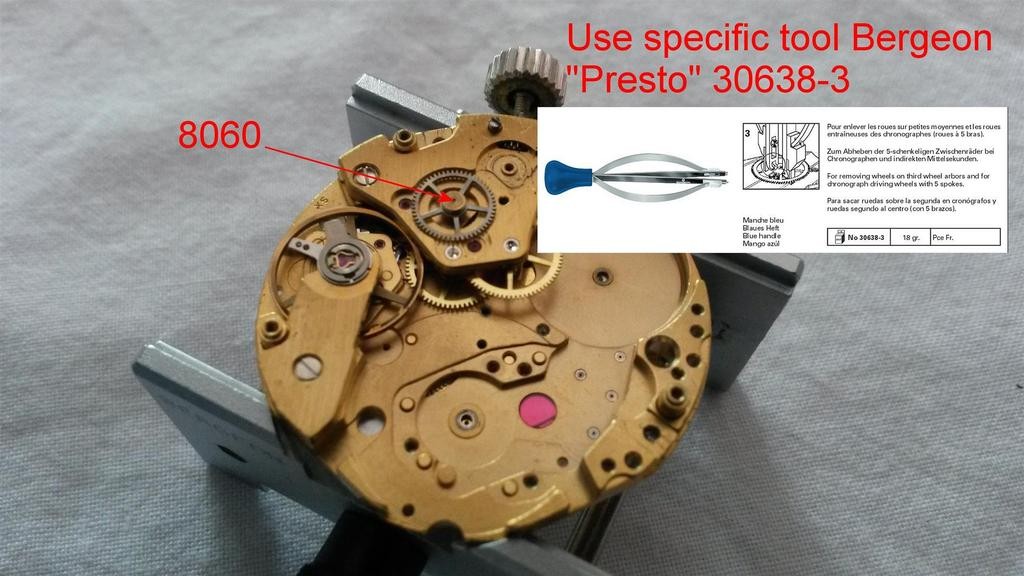

Remove the 8060 driving wheel using the proper Bergeon tool:

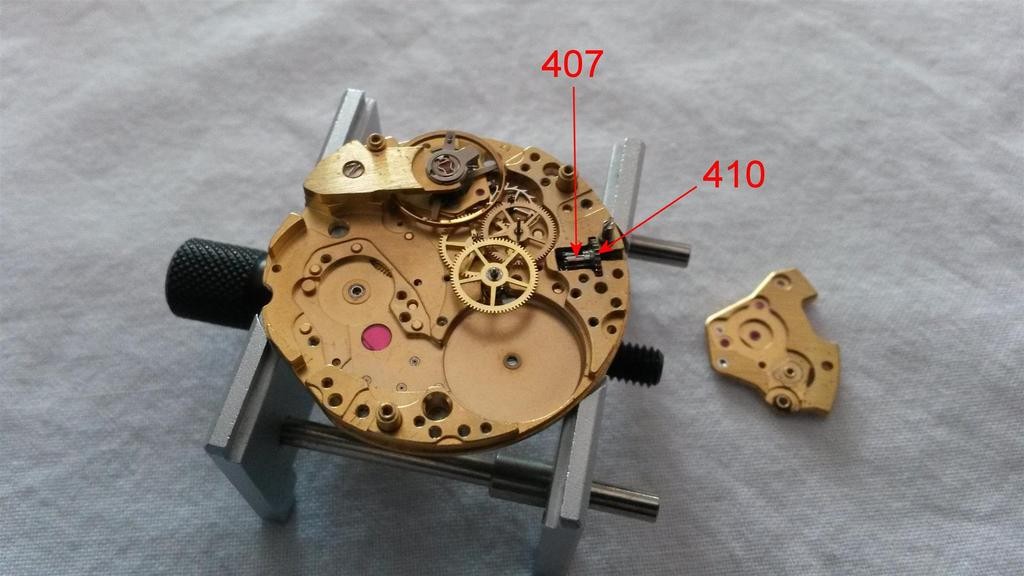

Now the 110 train wheel bridge and its screw 5110 (if, after uncasing the movement, you again put the stem with the crown, you must re-open its screw 5443 by 1.5 turns and pulling out the stem):

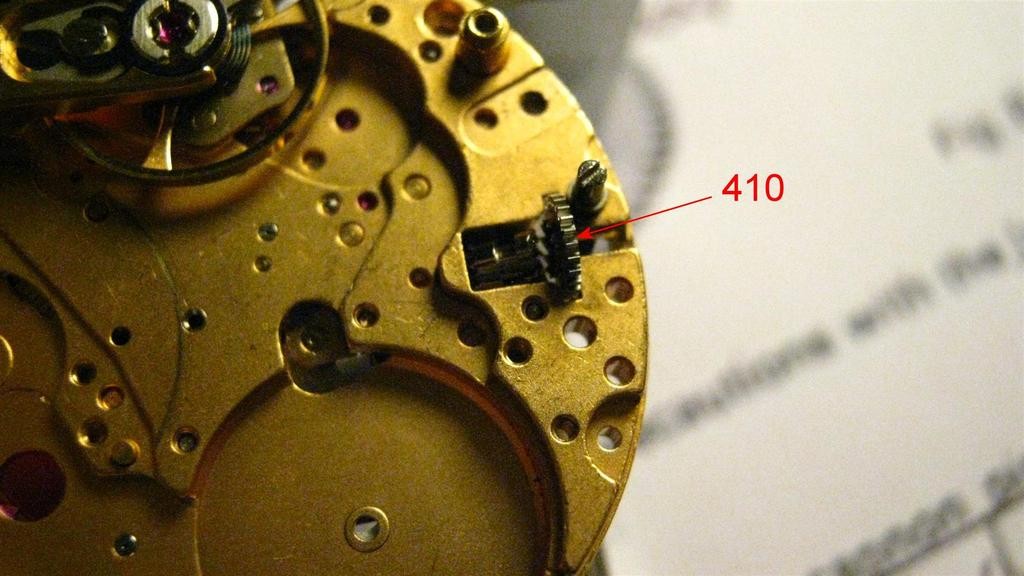

Now the 407 clutch wheel and 410 winding pinion:

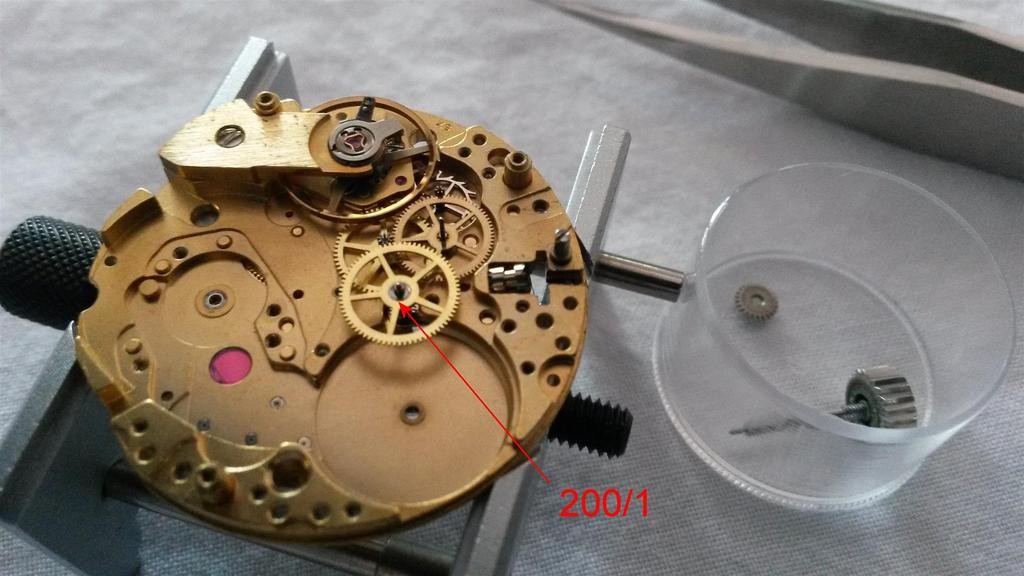

Now the 200/1 large driving wheel with cannon pinion:

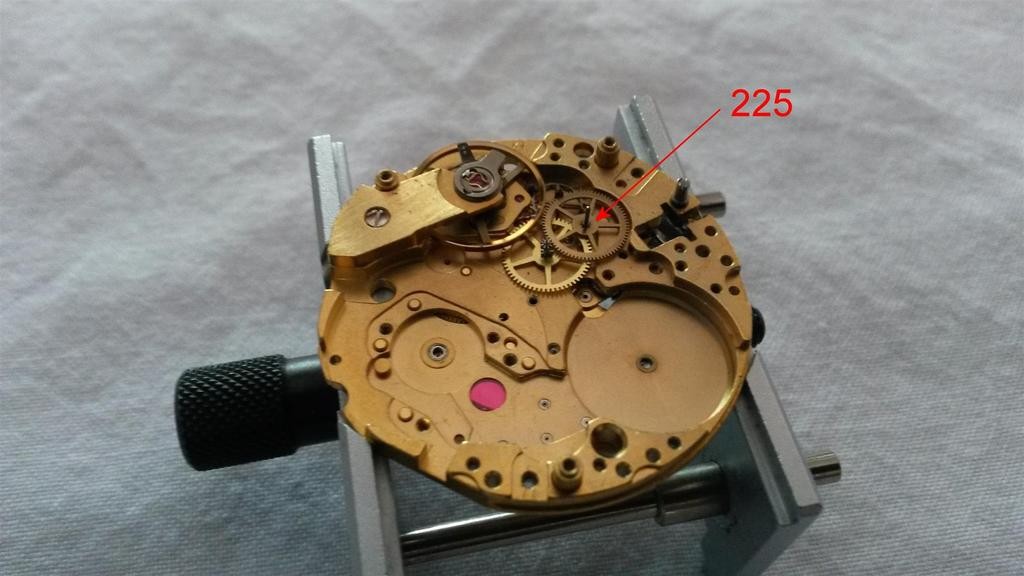

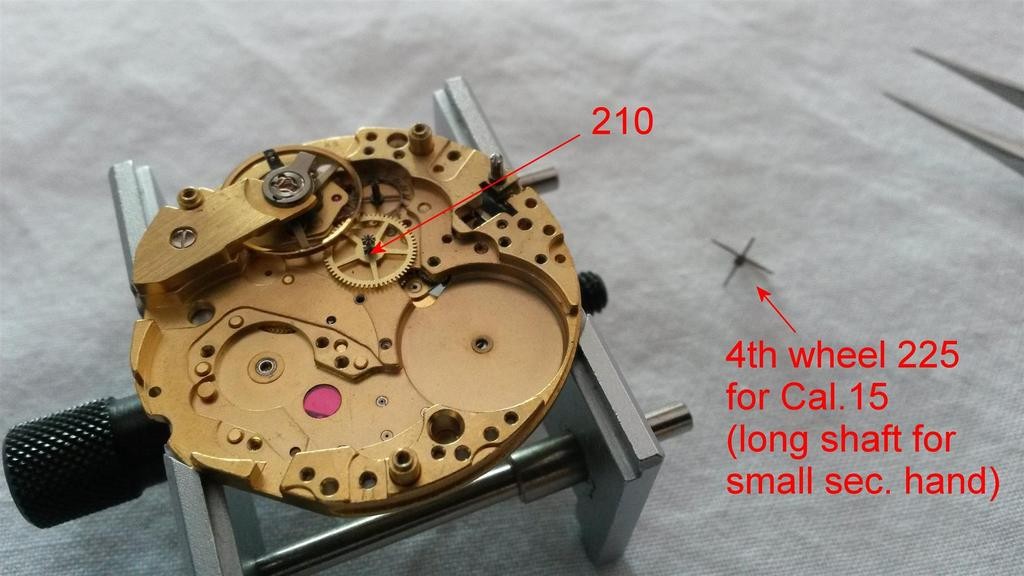

the 225 fourth wheel (in the Cal 15 supports the small seconds hand at 10 o’clock):

the 210 third wheel:

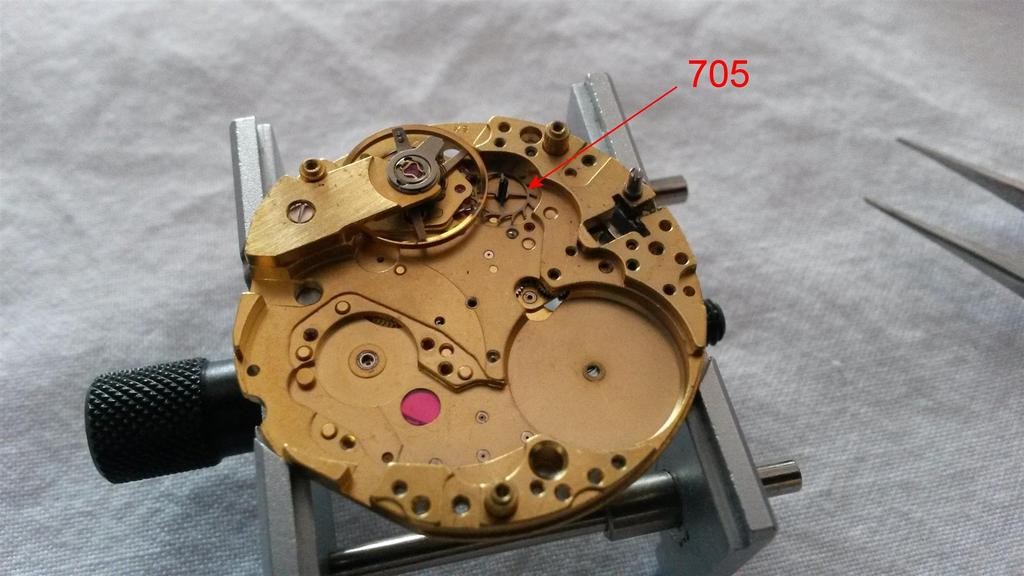

and finally the 705 escape wheel:

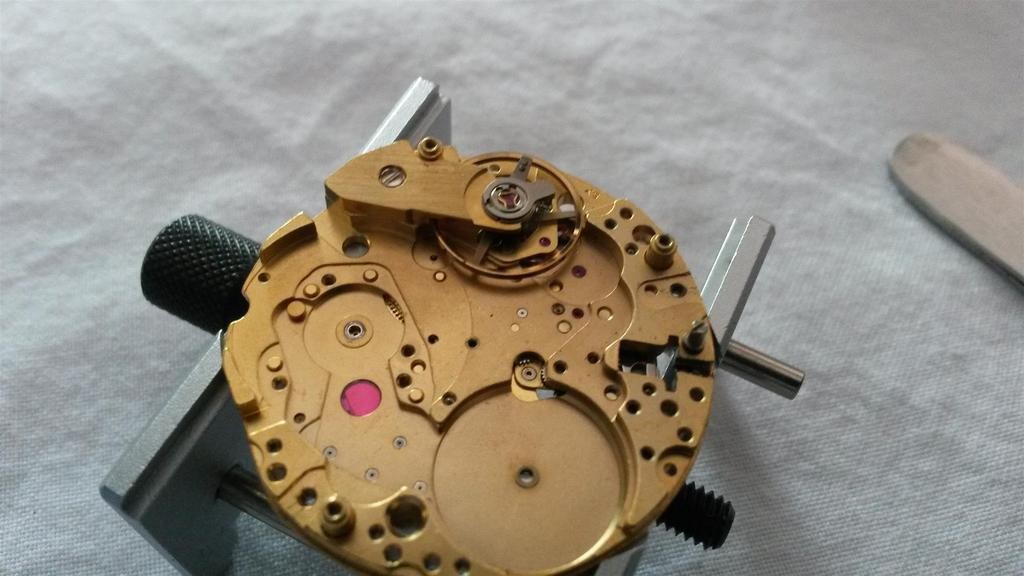

and you will have the main plate free from any wheel (balance wheel apart):

Turn the movement on the dial side and start disassembling it.

First unscrew the 52535 ones and gently pull-up the 2535 date indicator guard (take care not to damage the date disc):

Now remove the 2557/1 date indicator, the 469 hour wheel guard and the 2576 date jumper (notice that its 2575 spring will remain attached to the 2535 date indicator guard):

Now pull up the 2558 double-toothed hour wheel (which supports the hour hand) and the 243 cannon pinion (which supports the minute hand):

Now the 2556/1 date indicator driving wheel:

Remove the 462 minute work cock and its screws 5462:

Then the 260 minute wheel:

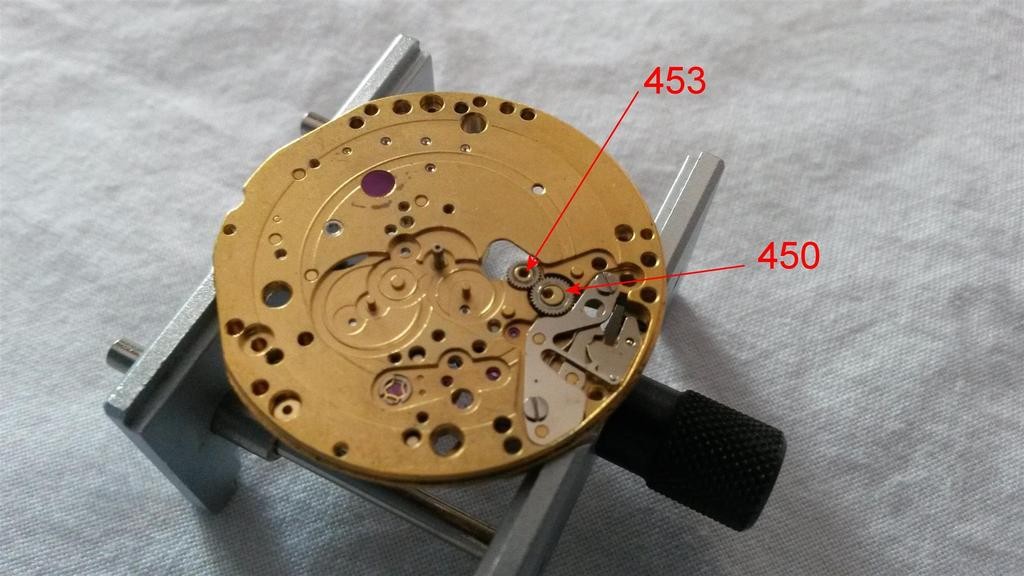

the 453 additional setting wheel and the 450 double setting wheel:

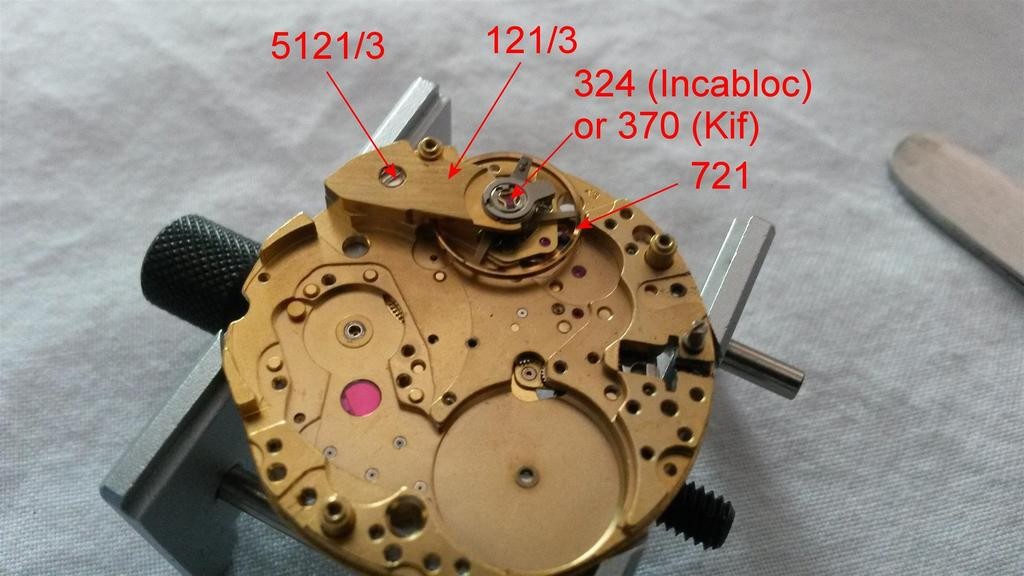

Turn the movement again and let’s go with the 721 balance wheel and its 121/3 bridge (correct name is balance cock for stud holder and shock-protecting device), then open the Incabloc (for Cal 11/12/14) or Kif (for Cal 15) golden spring (lyre shaped) and remove the 324 Incabloc upper jewel or 370 Kif upper jewel. (The first time I did this, I lost it squeezing out from the pliers, then understood that a small ball of Rodico with a toothpicker can help a lot 🙂 ):

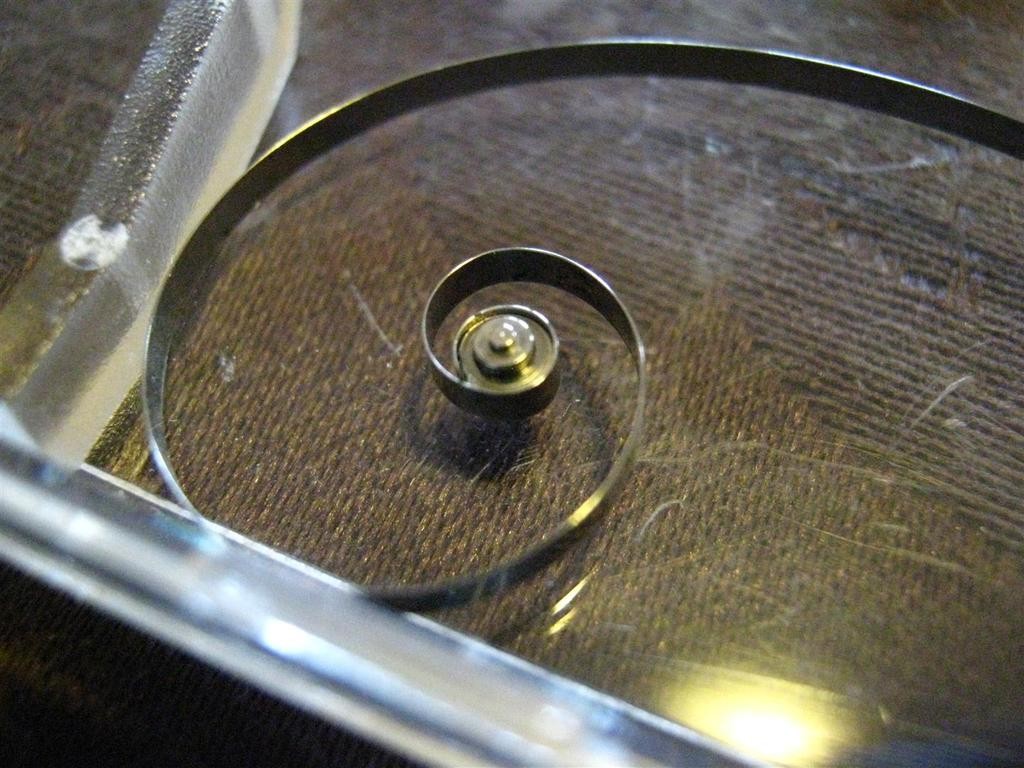

Close the Incabloc (or Kif) spring to avoid losing it and handle the balance wheel with care, its hairspring is the most delicate part of the watch:

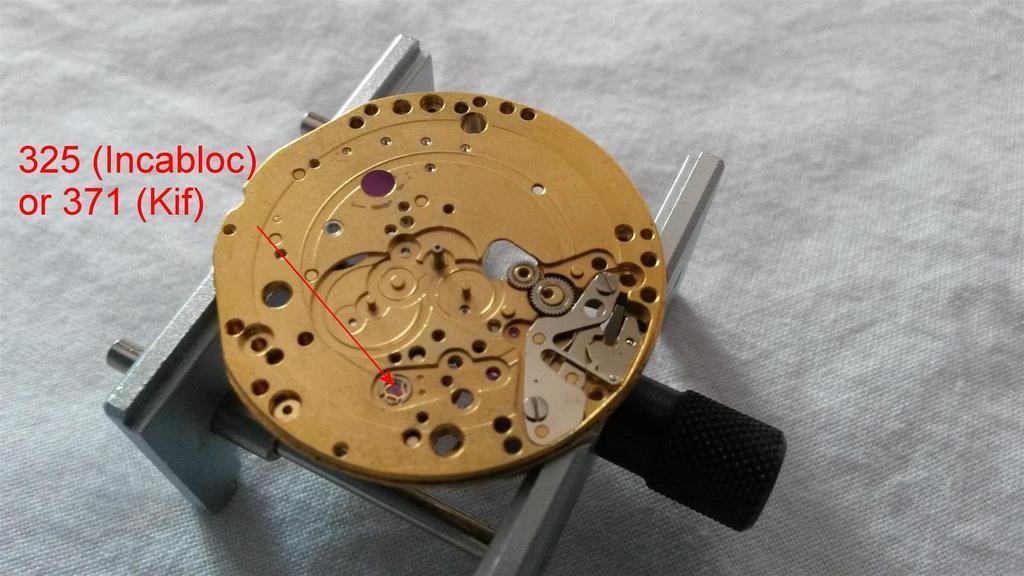

Do the same thing on the dial side, removing the 325 Incabloc lower jewel from its case (or 371 for Cal 15):

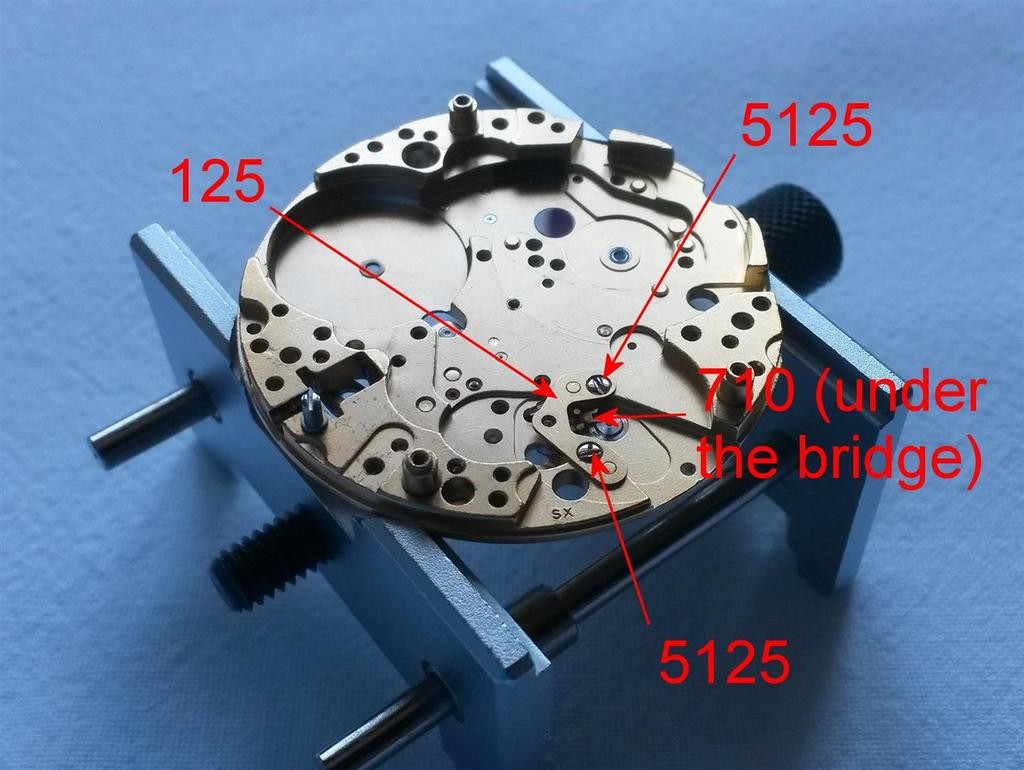

then the 125 pallet cock (unscrew the two 5125 ones) and the 710 pallet fork:

If you need to service the mainspring (highly recommended), you must open the barrel pushing it on a hard surface, take care that the mainspring will squeeze out, so do it gently:

then remove the 195 barrel arbor:

and you will have the mainspring ready to wash and put back again, using the specific Bergeon tool (mainspring winder):

This is my Monza completely disassembled, ready to wash and to be oiled and reassembled (but this is another long story):

Before leaving you all I want to thank the person (pro watchmaker) who helped me a lot every time I had a problem or had an undocumented step to do — you know who you are, and without your help I would never have been able to do it by myself, so thank you from the bottom of my heart 😉

I hope you will have enjoyed this posting, if you have arrived here at the end.

Cheers.

Gianluca